As part of a £17 million runway resurfacing and rehabilitation programme, our team was entrusted with delivering the detailed geospatial data needed to ensure this critical infrastructure continues to operate safely, efficiently, and to the highest standard.

Our teams thrive in high-pressure environments and ensure the standard of quality of our work is consistent on every project we are entrusted with.

Project background

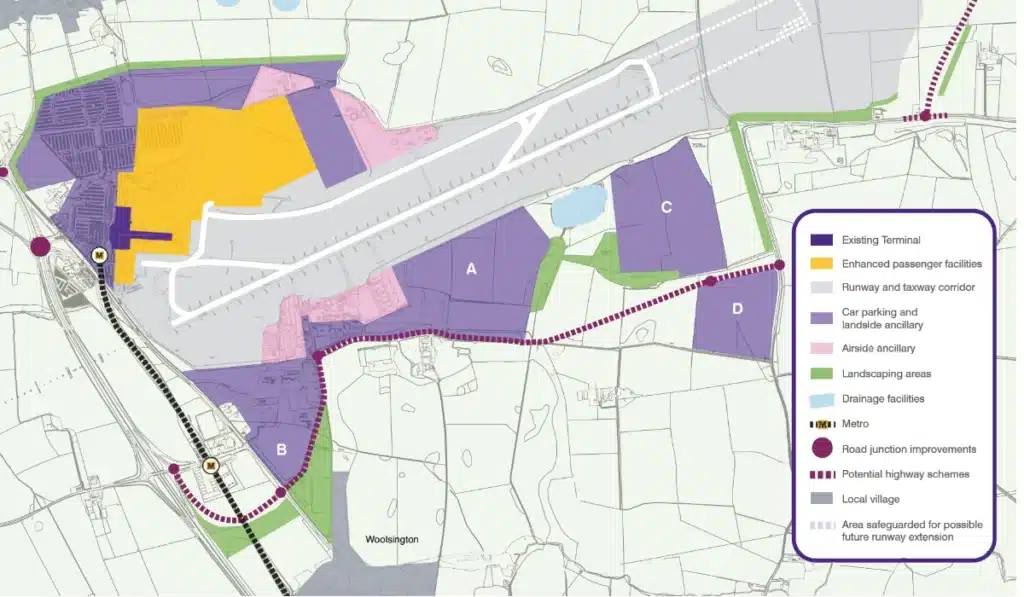

The airport’s main runway – a 2,323 metre long stretch of critical aviation infrastructure required essential resurfacing to extend its lifespan and prepare for future growth. This work formed a key part of the airport’s long-term Masterplan, which focuses on accommodating increasing passenger demand, larger aircraft, and enhanced operational efficiency.

Our involvement began in August 2024 with the delivery of a comprehensive topographical survey to support the detailed planning of the resurfacing works. Once construction began in November 2024, our scope expanded to include machine control set-up, precision setting out, surfacing checks, and as-built verification throughout the build process.

Following our successful involvement in the winter resurfacing phase, we were re-engaged to deliver a topographical survey and PAS 128 utility mapping as part of ongoing rehabilitation works, focusing on validating existing levels, mapping buried services, and providing up-to-date datasets for the next stages of airfield improvement.

Our Approach:

Our role was comprehensive, covering multiple survey disciplines and ensuring that the works were executed with exceptional precision.

Initial Surfacing phase (november 2024)

- We undertook a detailed topographical survey to support redesign and validate existing levels, this included:

- Establishing a high-precision control network across the airfield.

- Conducting thorough levelling over asphalt surfaces, soft ground transitions, and changes in surface materials.

- Mapping key features including manholes, drainage systems, pits, gullies, and other airfield infrastructure.

We supported the excavation and resurfacing works with machine control set-up using Topcon’s SmoothRide system, ensuring heavy plant machinery operated to exact design specifications. We also carried out precise setting out for key construction elements.

Accurately set out drainage, kerbs, and other airfield features; performed levelling checks throughout each shift to maintain exact tolerances.

Captured final surface levels at each stage, providing the client with complete verification data for quality assurance.

Follow up engagement:

Used traditional survey methods to establish control and carry out through levelling across multiple areas mapping: asphalt surfaces, soft ground transitions, changes in surface materials.

In parallel, we conducted a PAS 128-compliant utility survey to accurately map buried services across both soft and hardstanding areas. This included:

- Locating and recording runway lighting ducts, communications infrastructure, drainage, and ring mains.

- Providing the client with accurate service location data to prevent costly and disruptive strikes during future works.

Challenges and solutions:

Tight Night-Time Working Windows: All airside works were completed between the final flight departure at night and the first arrival in the morning. This required meticulous planning, efficient execution, and seamless communication with multiple teams on site.

Live Operational Environment: Safety and coordination were paramount when working in an active airport setting. Our team adhered to strict airside protocols while ensuring there was no disruption to day-to-day operations.

Delivering Millimetre Accuracy: Aviation projects demand extremely tight tolerances – even the smallest deviation can impact performance. Our combination of experienced surveyors, robust methodology and advanced equipment delivered consistent millimetre-level accuracy across all survey outputs.

Impact

By combining advanced geospatial technology with high-accuracy survey methods, we delivered a complete surface and subsurface dataset that underpinned every stage of the works. The integration of machine control, PAS 128 utility mapping, and as-built verification provided the client with:

- Confidence in the accuracy of design and construction alignment

- Streamlined operations, with survey data flowing seamlessly into construction workflows

- Compliance with the strict safety and operational requirements of a live airport

The resurfaced and rehabilitated runway now has the precision-engineered foundations needed to perform at the highest level for years to come, supporting Newcastle International Airport’s role as a vital transport hub for the region.

For our team, it’s incredibly rewarding to contribute to a project of this scale, one that directly supports regional connectivity, economic development, and the long-term resilience of critical infrastructure. From detailed surveys and modelling to precision setting out and quality checks, our work has been instrumental in ensuring the runway is fit for the demands of modern aviation.

As the project continues to progress, we remain committed to delivering the same level of accuracy, expertise, and collaboration that has underpinned every stage so far. Newcastle International Airport’s Masterplan is a vision of growth, and we are proud to have played a vital role in laying the groundwork for its future success.

Leeds

Leeds Doncaster

Doncaster Sheffield

Sheffield Bradford

Bradford Hull

Hull Halifax

Halifax Sunderland

Sunderland Newcastle

Newcastle Middlesborough

Middlesborough Yorkshire Moors

Yorkshire Moors Teesside

Teesside Cumbria

Cumbria Harrogate

Harrogate Teesdale

Teesdale York

York Yorkshire Dales

Yorkshire Dales Northumberland

Northumberland Goole

Goole Carlisle

Carlisle Keswick

Keswick Kendal

Kendal Barrow-in-Furness

Barrow-in-Furness Lancaster

Lancaster Blackpool

Blackpool Morecambe

Morecambe Southport

Southport Liverpool

Liverpool Wigan

Wigan Manchester

Manchester Blackburn

Blackburn Burnley

Burnley Forest of Bowland

Forest of Bowland Oldham

Oldham Chester

Chester Stockport

Stockport Peak District

Peak District Skipton

Skipton Crewe

Crewe Rotherham

Rotherham Stoke

Stoke Driffield

Driffield